WEB Catalog

Product List

- Air Management System

-

Directional Control Valves

- Pilot Operated 4/5 Port Solenoid Valves

- Pilot Operated 3 Port Solenoid Valves

- Direct Operated 3/4/5 Port Solenoid Valves

- Reduced-wiring Fieldbus System (Serial Transmission System)

- Wireless System

- Air Operated Valves

- Mechanical Valves/Transmitters

- Finger Valve/Hand Valves/Residual Relief 3 Port Valve

- Blow Guns

- Power Valves

- ISO Valves

- Explosion-Proof Valves

- Pilot Operated 4/5 Port Solenoid Valves

-

Air Cylinders

- Standard Air Cylinders (Round Type)

- Standard Air Cylinders (Square Cover)

- Compact Air Cylinders

- Environment Resistant Cylinders

- Floating Joints/Rod End

- Air-hydro Units

- Mechanically Jointed Rodless Cylinders

- Magnetically Coupled Rodless Cylinders

- Table Cylinders

- Guide Cylinders

- Dual Rod Cylinders

- Lock Cylinders/Cylinder with An End Lock

- Fine Lock Cylinders

- Specialty Cylinders

- Clamp Cylinders

- Pin Shift Cylinder

- Stopper Cylinders

- Stroke Reading Cylinders

- Valve Mounted Air Cylinders

- ISO Cylinders: ISO Standards (6432)

- ISO Cylinders: ISO Standards (15552)

- ISO Cylinders: ISO Standards (21287)

- ISO Cylinders

- Shock Absorbers

- Auto Switches

- Wireless Auto Switches

- Actuator Position Sensor

- Flow Control Equipment

- Standard Air Cylinders (Round Type)

- Rotary Actuators/Air Grippers

-

Electric Actuators/Cylinders

- e-Actuator

- Manifold Controller/Manifold Controller Compatible Electric Actuator

- Battery-less Absolute Encoder Type

- Slider Type

- Rod Type/Guide Rod Type

- Slide Tables

- Miniature

- Rotary Tables

- Grippers

- Grippers for Collaborative Robots

- Controllers/Drivers

- Environment

- Motorless Type

- Mounting Kit for Multi-Axis System

- Electric Cylinders

- Card Motor

- Made to Order

- e-Actuator

-

Vacuum Equipment (Vacuum Generators/Vacuum Suction Cups/Other)

- Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

- Vacuum Ejectors

- Vacuum Gripper System (Foam Type)

- Vacuum Release Valve Units

- Air Suction Filters

- Vacuum Pads (Vacuum Suction Cups)

- Special Pads

- Gripper for Collaborative Robots

- Vacuum Saving Valves

- Magnet Buffer

- Vacuum Flow

- Vacuum Regulators

- Related Equipment for Vacuum Systems

- Vacuum Ejectors (Vacuum Generators)/Vacuum Pump Systems

- Grippers for Collaborative Robots

- Compact Compressor

- Air Preparation Equipment

- Modular F.R.L./Pressure Control Equipment

- Modular F.R.L. Units

- Pressure Control Equipment

- Booster Regulators

- Lubrication Equipment

- Gas Generator

- Fittings and Tubing

-

Flow Control Equipment

- Speed Controllers for General Purposes

- Speed Controllers for Low Speed Control

- Speed Controllers Special Environments

- Speed Controllers with Special Functions

- Tool Operation Type Speed Controllers

- Air Saving Speed Controllers Air Saving Valves

- Remote control valve (Electric speed controller)

- Related Equipment

- Speed Controllers for General Purposes

- Silencers/Exhaust Cleaners/Pressure Gauges

- Air Blowing Equipment

-

Switches/Sensors/Controller

- Electronic Pressure Switches/Sensors (Self-contained Type)

- Electronic Pressure Switches/Sensors (Remote Type)

- Mechanical Pressure Switches

- Electronic Flow Switches/Sensors

- Clamp-on Type Flow Sensor

- Mechanical Flow Switches

- Air Management System

- Controllers

- Electronic Temperature & Humidity Switches

- Auto Switches for Air Cylinders

- Auto Switches for Rotary Actuators and Air Grippers

- Position Sensor

- Electronic Pressure Switches/Sensors (Self-contained Type)

-

Static Neutralization Equipment

- Static Neutralization Equipment Ionizer Bar Type

- Static Neutralization Equipment Nozzle Type Ionizer

- Static Neutralization Equipment Fan Type Ionizer

- Static Neutralization Equipment Ionizer Gun

- Static Neutralization Equipment Desktop Duster Box

- Static Neutralization Equipment Electrostatic Sensor/Sensor Monitor/Meter

- Static Neutralization Equipment/Ionizers

- Static Neutralization Equipment Ionizer Bar Type

-

Industrial Device Communication Equipment/Wireless System

- Wireless System: PROFINET Compatible Products

- Wireless System: EtherNet/IP Compatible Products

- Wireless System: EtherCAT Compatible Products

- Wireless System: IO-Link Compatible Products

- Wireless System: CC-Link Compatible Products

- Wireless System: DeviceNet Compatible Products

- Industrial Device Communication Equipment: PROFINET Compatible Products

- Industrial Device Communication Equipment: EtherNet/IP Compatible Products

- Industrial Device Communication Equipment: EtherCAT Compatible Products

- Industrial Device Communication Equipment: Modbus TCP Compatible Products

- Industrial Device Communication Equipment: ETHERNET POWERLINK Compatible Products

- Industrial Device Communication Equipment: CC-Link IE Field Compatible Products

- Industrial Device Communication Equipment: SSCNET III Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅲ Compatible Products

- Industrial Device Communication Equipment: PROFIsafe Compatible Products

- Industrial Device Communication Equipment: IO-Link Compatible Products

- Industrial Device Communication Equipment: PROFIBUS Compatible Products

- Industrial Device Communication Equipment: DeviceNet Compatible Products

- Industrial Device Communication Equipment: CC-Link Compatible Products

- Industrial Device Communication Equipment: AS-interface Compatible Products

- Industrial Device Communication Equipment: CompoNet Compatible Products

- Industrial Device Communication Equipment: Interbus Compatible Products

- Industrial Device Communication Equipment: MECHATROLINK-Ⅱ Compatible Products

- Other: RS232C Compatible Products

- Other: RS485 Compatible Products

- Wireless System: PROFINET Compatible Products

- Process Valves

- Chemical Liquid Valves/Fittings & Needle Valves/Tubing

- Process Pumps(Diaphragm Pumps)

-

Temperature Control Equipment

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Inverter Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Dual Channel Thermo chiller for Lasers

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Rack Mount Type

- Thermo-Chillers (Circulating Fluid Temperature Controllers) High performance/Type & Inverter Type

- Chiller Compliant Regulations

- Thermo-cons/Thermoelectric Baths (Peltier-Type Temperature Control Equipment)

- Air Temperature Controllers

- Thermo-Chillers (Circulating Fluid Temperature Controllers) Standard Type/Basic Type

- Process Gas Equipment AP Tech

- High Vacuum Equipment

- Industrial Filters/Sintered Metal Elements

- Pneumatic Instrumentation Equipment

- Hydraulic Equipment

Theme

-

Clean Series/Low-Particle Generation

- Directional Control Valves

- Air Cylinders

- Rotary Actuators

- Air Grippers

- Air Dryers

- Compressed Air Cleaning Filter Series

- Clean Gas Filters/Air Filters

- Exhaust Cleaner for Clean Room/Clean Exhaust Filter

- Modular F.R./Pressure Control Equipment

- Fittings

- Tubing

- Flow Control Equipment

- Switches/Sensors

- Flow Switch

- Electric Actuators

- Directional Control Valves

- Fluoropolymer Equipment/PVC Equipment

-

Series Compatible with Secondary Batteries Series 25A-

- Air Management System

- Directional Control Valves

- Actuators

- Related Products

- Rotary Actuators/Air Grippers

- Vacuum Equipment

- Air Preparation Equipment/Clean Air Filters

- ModularF.R.L./Pressure Control Equipment

- Flow Control Equipment/Fittings

- Tubings

- Detection Switches/Auto Switches

- Static Neutralization Equipment/Ionizers

- Process Valves

- Process Gas Equipment

- Electric Actuators

- Air Management System

- Copper, Fluorine-free Equipment Series 20-

- ISO Products

- Arc Welding Process Equipment

- IO-Link Compatible Products

- Grease-free Nitrogen (N2) Compatible Equipment

- List of ATEX Compliant Products

- Explosion-Proof Valves Certified Products

- Equipment for the Food Manufacturing Industry

- Equipment for the Semiconductor Industries

Standard Air Cylinders (Square Cover)

Air Cylinder CS2/CDS2

-

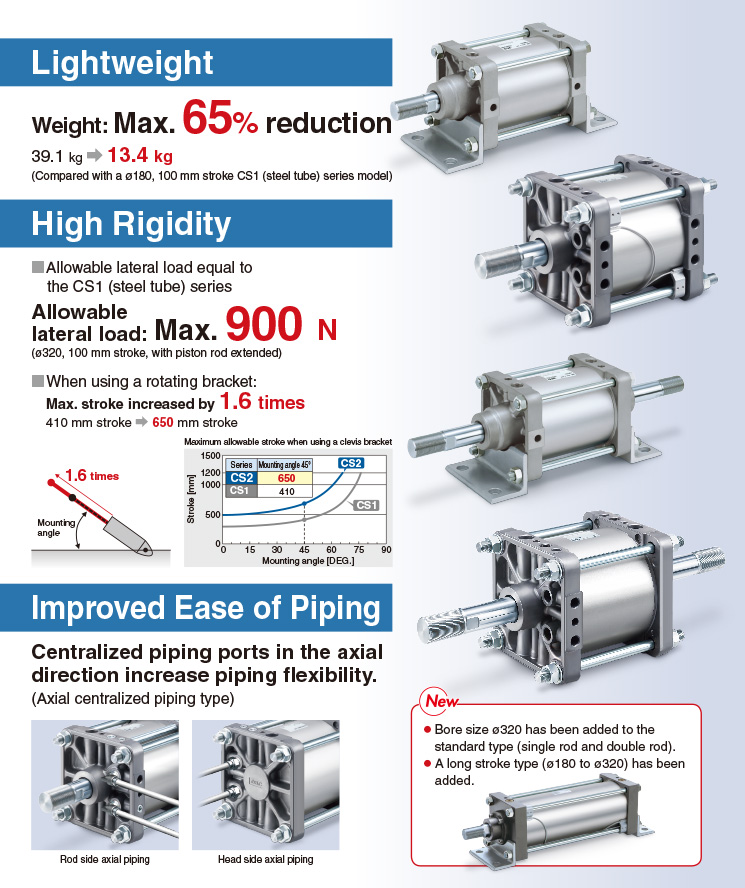

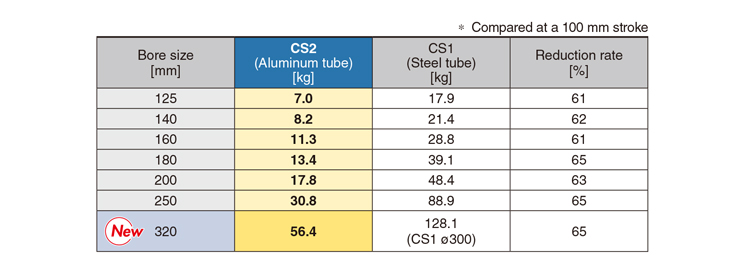

・Lightweight: Weight reduced by up to 65% (39.1 kg → 13.4 kg)

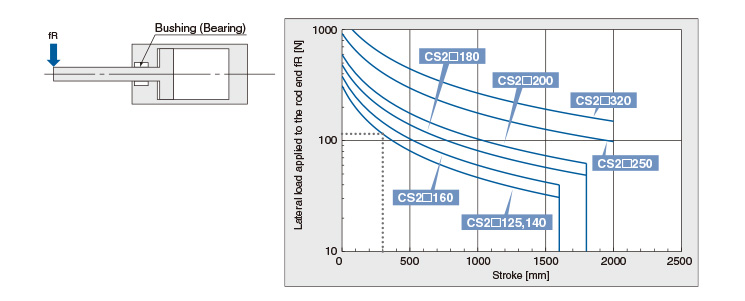

・High rigidity (Allowable lateral load: Max. 900 N)

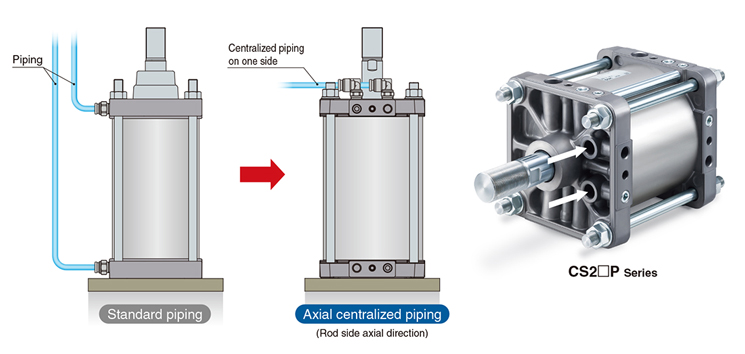

・Improved ease of piping:

Centralized piping ports in the axial direction increase piping flexibility.

(Axial centralized piping type)

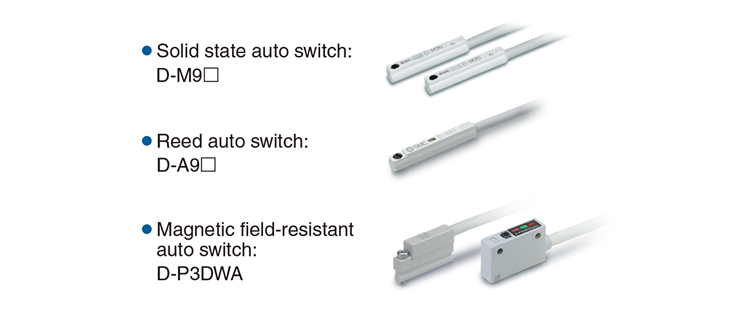

・With auto switch (CDS2 series: CDS2)

-

2D/3D CAD

The new SMC CAD SYSTEM, CADENAS, allows you to output 2D/3D CAD data with full part numbers in various data formats. Responses to part number selection has been greatly improved with the newly developed system.

Click here for 2D/3D CAD2D CAD

Click here for 2D CAD Air Cylinder CS2/CDS2

Manual

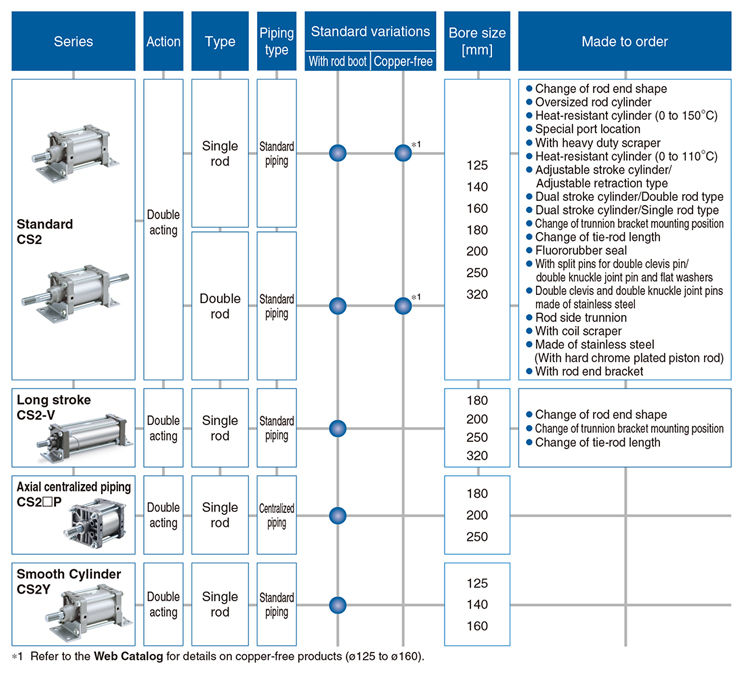

Type Series Action Bore size (mm) View search result Standard CS2 Double acting, Single rod 125,140,160,180,200,250 View search result Standard CS2W Double acting, Double rod 125,140,160,180,200,250 View search result A long stroke CS2-V Double acting, Single rod 180,200,250,320 View search result Axial centralized piping CS2□P Double acting, Single rod 180,200,250 View search result Air Cylinder CS2/CDS2

Symbol Specifications Download -XA0 to XA30 Simple Specials Change of rod end shape PDF -XC14 Simple Specials Change of trunnion bracket mounting position PDF -XC15 Simple Specials Change of tie-rod length PDF Air Cylinder CS2/CDS2

Symbol Specifications Download -XB6 Made to Order Common Specifications Heat resistant cylinder (-10 to 150℃) PDF -XC3 Made to Order Common Specifications Special port location PDF -XC4 Made to Order Common Specifications With heavy duty scraper PDF -XC5 Made to Order Common Specifications Heat resistant cylinder (-10 to 110℃) PDF -XC9 Made to Order Common Specifications Adjustable stroke cylinder/Adjustable retraction type PDF -XC10 Made to Order Common Specifications Dual stroke cylinder/Double rod type PDF -XC11 Made to Order Common Specifications Dual stroke cylinder/Single rod type PDF -XC22 Made to Order Common Specifications Fluororubber seals PDF -XC26 Made to Order Common Specifications With split pins for double clevis pin/double knuckle joint pin and flat washers PDF -XC27 Made to Order Common Specifications Double clevis and double knuckle joint pins made of stainless steel PDF -XC30 Made to Order Common Specifications Rod side trunnion PDF -XC35 Made to Order Common Specifications With coil scraper PDF -XC36 Made to Order Common Specifications With boss in rod side PDF -XC65 Made to Order Common Specifications Made of Stainless Steel (Combination of XC7 and XC68) PDF -XC68 Made to Order Common Specifications Made of stainless steel (with hard chrome plated piston rod) PDF -XC86 Made to Order Common Specifications With rod end bracket PDF

Auto Switches/Precautions Model Selection/Technical Data

Simple Specials Made to Order Common Specifications Green Procurement (RoHS)

| Type | Series | Action | Bore size (mm) |

|---|---|---|---|

| Standard | CS2 | Double acting, Single rod | 125,140,160,180,200,250 |

| Standard | CS2W | Double acting, Double rod | 125,140,160,180,200,250 |

| A long stroke | CS2-V | Double acting, Single rod | 180,200,250,320 |

| Axial centralized piping | CS2□P | Double acting, Single rod | 180,200,250 |

Features

Lightweight, High Rigidity, Improved Ease of Piping

Lightweight

Weight reduced by a change in the cover material

High Rigidity

Allowable lateral load: Max. 900 N(ø320, 100 mm stroke, with piston rod extended)

Ease of piping improved by placing the piping and cushion valve on the same side

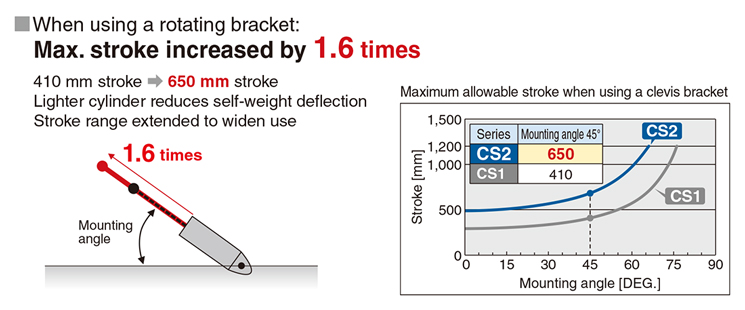

Mounting is interchangeable with the CS1 series.

・Interchangeable cylinder mounting dimensions

・Interchangeable rod end thread sizes

Lateral load equal to the CS1 series

Air cushion + bumper cushion combined structure

The bumper cushion reduces the metal noise that occurs when the piston stops at the end of the stroke. (ø180, ø200, ø250, and ø320 only)

Auto switches can be mounted on ø125 to ø320.

Smooth Cylinder CS2Y Series (ø125 to ø160 only)

・Min. operating pressure: 0.005 MPa

・For stable operation even at low speeds of 5 mm/s

Axial Centralized Piping (ø180, ø200, and ø250 only)

Increased piping flexibility, Reduced piping labor

・Piping ports are located in the axial direction of the head cover or the rod cover.

・For long-stroke operation, the speed can be adjusted on one side. Furthermore,

the piping has been simplified, resulting in improved ease of piping.

Series Variations