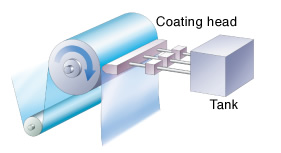

|6. Coating

Film is coated with various types of solvents, depending on the application.

Various Acidic and Alkaline Chemical Solution Atmospheres

| Use | Item name | Series |

|---|---|---|

| Improved corrosion resistance |

Air Operated Chemical Valve | LV |

| Fluororesin Fittings/Hyper Fitting | LQ1 | |

| Fluororesin Fittings/Hyper Fitting Flare Type | LQ3 | |

| Stainless Steel Cylinder | CJ5・S / CG5・S | |

| Floating Joint (Stainless Steel) | JS | |

| Stainless Steel 316 One-touch Fittings | KQG | |

| Stainless Steel 316 Insert Fittings | KFG | |

| FEP Tubing | TH / TIH | |

| Fluororesin Tubing | TL / TIL |

Solvent Transfer

| Use | Item name | Series |

|---|---|---|

| Explosion-proof equipment |

Intrinsically Safe Explosion-proof System 5 Port Solenoid Valve |

51-SY |

| *5 Port Solenoid Valve | SY | |

| *5 Port Solenoid Valve | VQC | |

| Diaphragm pump | Fluororesin Process Pump | PA / PAP |

| Process Pump | PAF |

* For use in non-explosion proof areas.

Prepared Solution Sending Control

| Use | Item name | Series |

|---|---|---|

| Reduced-wiring system |

Serial Transmission System | EX120 |

| Serial Transmission System | EX510 | |

| Manifold with SUP Stop Valve | SS5Y□-X460 | |

| Explosion-proof equipment |

Intrinsically Safe Explosion-proof System 5 Port Solenoid Valve |

51-SY |

Points and Precautions for Selection

• Please use a low-power-consumption solenoid valve if you plan to keep the solenoid valve energized for extended periods

of time. Please refer to page 26 for details.

• Using equipment in a solvent atmosphere may result in diminished product quality, so please check the specifications and

materials of the model.

• When using equipment at high temperatures or in a solvent atmosphere, please check the specifications (operating

temperature, materials, etc.) of the model.

• Through the use of a manifold with an SUP stop valve (refer to page 3), it is possible to replace equipment incrementally

without causing an overall stop of the line, allowing for faster restarting of operation.

• When working in an explosion-proof area, please select explosion-proof equipment.

• When using in a clean environment, please select equipment that conforms to clean-room class standards of cleanliness.

Temperature and Flow Control of Chemical Solutions

| Use | Item name | Series |

|---|---|---|

| Temperature control | Thermo-cooler (Constant temperature water circulating device) |

HRS |

| Thermo-cooler (Constant temperature fluid circulating device <High performance type>) | HRZ | |

| Flow Switch | PFM / PF2A/ PF3A7□H / PF3W |

Points and Precautions for Selection

• A stable and even coating is made possible by keeping the roll and the solvent at a constant temperature. A chiller allows for high-precision temperature control.

Anti-ozone Measures

| Use | Item name | Series |

|---|---|---|

| Anti-ozone Equipment |

Anti-ozone Equipment |

Deaeration Treatment

| Use | Item name | Series |

|---|---|---|

| High vacuum valve | Stainless Steel High Vacuum Angle Valve | XM |

| Stainless Steel High Vacuum In-line Valve | XY | |

| High Vacuum Straight Solenoid Valve | XSA |

Clean Room Specifications

| Use | Item name | Series |

|---|---|---|

| Pneumatic equipment for clean room |

Clean Series | Clean Series |

Preventing Attachment of Foreign Objects

| Use | Item name | Series |

|---|---|---|

| Anti-static electricity measures, clean blow |

Ionizer | IZS 40 / 41 / 42 |

| Clean blow | Clean Air Module | LLB |