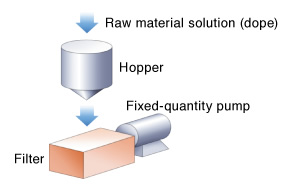

|1. Dissolution of Raw Materials

Dried chips of raw material (PET) are

fed into a hopper, then supplied to an

extruder and completely melted down.

Blending of Raw Materials

| Use | Item name | Series |

|---|---|---|

| Explosion-proof equipment | Intrinsically Safe Explosion-proof System 5 Port Solenoid Valve | 51-SY |

| *5 Port Solenoid Valve | SY | |

| *5 Port Solenoid Valve | VQC | |

| Industrial Filters | Industrial Filter | FG |

* Does not meet explosion-proof specifications. Please use only in non-explosion proof areas.

Solvent Atmosphere

| Use | Item name | Series |

|---|---|---|

| Improved corrosion resistance | Stainless Steel Cylinder | CJ5・S / CG5・S |

| Floating Joint (Stainless Steel) | JS | |

| Stainless Steel 316 One-touch Fittings | KQG | |

| Stainless Steel 316 Insert Fittings | KFG | |

| FEP Tubing | TH / TIH | |

| Fluororesin Tubing | TL / TIL | |

| Clean Regulator | SRH |

Air-conditioning Duct Control / Raw Material Quantity Control

| Use | Item name | Series |

|---|---|---|

| Duct opening control Valve opening control Instrumentation system |

Electro-Pneumatic Positioner | IP8000 / 8100 |

| Precision Regulator | IR1000 / 2000 / 3000 |

Points and Precautions for Selection

• When using in an explosion-proof area, please select explosion-proof equipment.

• Please use a low-power-consumption solenoid valve if you plan to keep the solenoid valve energized for extended periods

of time. Please refer to page 26 for details.

• Using equipment in a solvent atmosphere may result in diminished product quality, so please check the specifications and

materials of the model.

• When using equipment at high temperatures or in a solvent atmosphere, please check the specifications (operating temperature,

materials, etc.) of the model before using.