Solutions » SMC's Proposal » Proposal for Installation of Thermo-chiller » Proposal for Thermo-chiller used with Arc Welding Machines (water-cooled) »

Application Examples

|Application Examples

The following are some of the application examples. Since the amount of heat generated changes with conditions and usage rates, the effectiveness is not guaranteed.

[Equipment] Water-cooled Arc Welding Machine

| Specifications | CO2welding (400 A) |

|---|---|

| Chiller type | HRS018-A-20-T + HRS-BP001 (Bypass piping) |

| Application |

Welding of construction machinery parts

Changed from radiator type to a thermo-chiller. |

| Effect |

The set temperature could be maintained, which

extended the life of the welding tip, and reduced costs.

⇒ Greatly reduced tip replacement costs |

[Equipment] General-purpose TIG Welding Machine

| Specifications | Rated output current value 300 A |

|---|---|

| Chiller type |

HRSE018-A-20-T

HRSE012-A-20-T + HRS-BP001 (Bypass piping) |

| Application |

Stainless tank welding

Changed from radiator type to a chiller. |

| Effect | Stable water temperature reduced the consumption of the tungsten electrode and power cable. The durability of the collet also improved. By suppressing the increase of the torch tem perature, continuous manual welding became possible. |

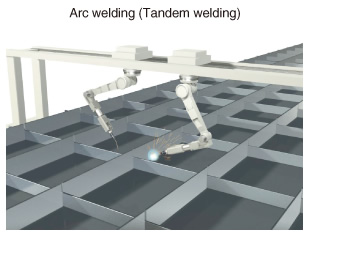

[Equipment] Water-cooled Arc Welding Machine (Tandem Welding)

| Specifications | Tandem CO2 welding (450 A) + CO2 welding (400 A) |

|---|---|

| Chiller type | HRS050-A-20 + HRS-BP004 (Bypass piping) |

| Application | Thick material continuous welding. Although two radiator types were used conventionally, the improved life of the tip and the cooling system are integrated into one unit. |

| Effect | When a radiator was used, the water temperature increased immediately after the welding started, and the tip eventually disappeared. After the chiller was introduced, the water temperature stabilized immediately after the welding started, and the set temperature was maintained. The life of the tip was greatly improved. Furthermore, spatter was reduced, and a stable bead formation was obtained. |

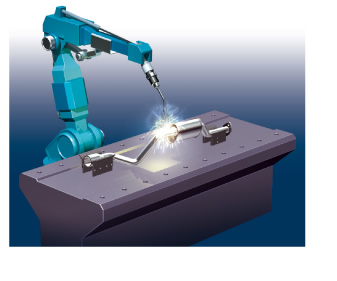

[Equipment] Plasma Welding Machine

| Specifications | Plasma welding machine (300 A) |

|---|---|

| Chiller type | HRS050-A-20 + HRS-BP004 (Bypass piping) |

| Application | The cooling of the water-cooled torch used on a muffler plasma welding robot. |

| Effect | Cooling water at a stable temperature can be supplied even in plasma welding with high radiant heat. The costs of expensive argon gas could be reduced due to turbulence suppression. The wear of the torch tip was also suppressed. |