Solutions » SMC's Proposal » Proposal for Installation of Thermo-chiller »

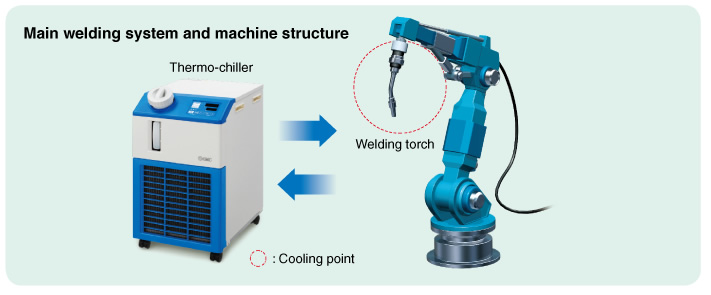

Proposal for Thermo-chiller used with Arc Welding Machines (water-cooled)

|Proposal for Thermo-chiller used with Arc Welding Machines (Water-cooled)

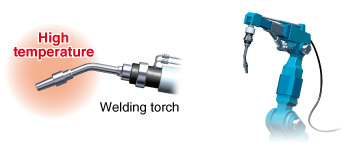

Solves problems caused by insufficient cooling of “welding torches.”

When a welding torch reaches a high temperature,

various problems may arise.

Have you experienced any of the following problems?

Effects of rising torch temperature

- Process becomes unstable, which causes wavy beads (weld marks), and generates bubbles.

- Requires work-hours for polishing due to excessive scattering of spatter to surroundings.

- Tip life deteriorates due to softening.

Effects obtained by cooling and stabilizing the welding torch temperature

- Stable power supply produces stable beads (weld marks).

- Improved shielding reduces spatter scattering.

- Prevents softening of welding tips. Long life.

- Stable torch temperature improves operability of tip replacement.

- Can be used with large currents.

The use of a “Thermo-chiller” promotes improvement in both quality and operability. Reduce your costs and problems at once!