|Proposal for Thermo-chiller used with Resistance Welding Machines

Ground water

Since the water is too cold, dew condensation occurs in summer.

Cause of failures!

Cause of failures!

Ground water

Algae grow and adhere to the

inside of welding machines.

Cause of failures!

Cause of failures!

Tap water

High tap water costs (running costs)!

Radiator type circulation systems and cooling towers

Water temperature increases in summer.

Quality deteriorates and shortens life of tips!

Quality deteriorates and shortens life of tips!

Ground water

Set to 20 to 25°C

Cools without condensation.

Cools without condensation.

Stable water quality without foreign objects from the chiller.

Prevents the growth of algae by periodic replacement of water.

Cooling towers

Water temperature remains stable even in summer.

Extends the life of tips.Reduces maintenance requirements!

Extends the life of tips.Reduces maintenance requirements!

Even in poor surrounding environments, since the product is sealed,it is not affected by dust etc.

Tap water

Circulates the water in the tank.

Greatly reduces running costs.

Greatly reduces running costs.

Radiator type circulation systems

The stable water temperature, even during the summer, improves tip life and operability.

Wear particulate-free HRS series (Standard) does not require maintenance.

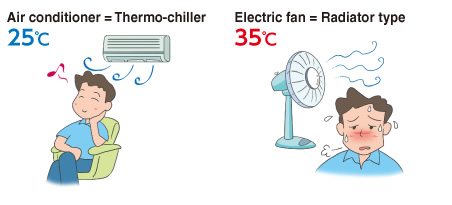

Difference between chiller and radiator type

The radiator type is not equipped with a

compressor, and the circulating water is

cooled by a fan. Therefore, the

temperature cannot be reduced below the

ambient temperature. For this reason, the

water temperature differs by season.

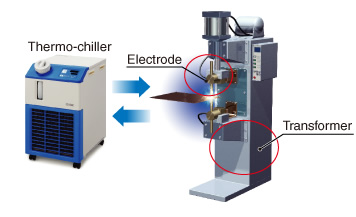

Cooling locations

AC: Electrodes (upper/lower), transformer (built-in)

DC: Electrodes (upper/lower), transformer (built-in), transistor (thyristor)