●For air

Applicable fluid: Air, nitrogen, argon, carbon dioxide

Air quality grade is JIS B 8392.1-1. 1.2 to 1.6.2 , ISO 8573.1-1. 1.2 to 1.6.2.

●For deionized water, chemicals

Applicable fluid: Deionized water

Ultrapure water

Fluids that does not corrode piping materials.

●For water

Applicable fluid: Water

Mixture of water (50%) and ethylene glycol (50%)

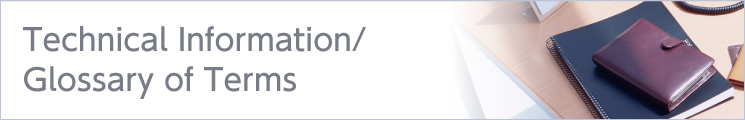

●Karman vortex

When an elongated object (vortex generator) is placed in the flow, reciprocal vortexes are generated on the downstream side. These vortexes are stable under certain conditions, and their frequency is proportional to the flow velocity, resulting the following formula.

f=k×v

f: Frequency of vortex v: Flow velocity k: Proportional constant (determined by the vortex generator's dimensions and shape). Therefore, the flow rate can be measured by detecting this frequency.

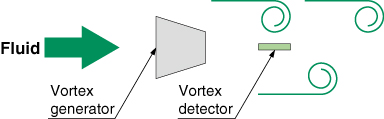

●Thermal type (MEMS)

This MEMS sensor chip consists of upstream temperature measuring sensor (Ru) and downstream temperature measuring sensor (Rd), which are placed symmetrically from the center of a platinum thin film coated heater (Rh) mounted on a membrane, and an ambient temperature sensor (Ra) for measuring gas temperature.

The principle is shown as the diagram below, the difference in resistance between Ru and Rd is proportional to the flow velocity, so measurement and analysis of the resistance can show the flow direction and velocity of the gas.

Ra is used to compensate the gas and/or ambient temperature.

This flow switch uses L/min as the flow rate indicator unit. The mass flow is converted and displayed under the conditions of 0°C and 101.3 kPa and 20°C and 101.3 kPa.

For air

Applicable fluid: Air, nitrogen, argon, carbon dioxide

Air quality grade is JIS B 8392.1-1. 1.2 to 1.6.2 , ISO 8573.1-1. 1.2 to 1.6.2.

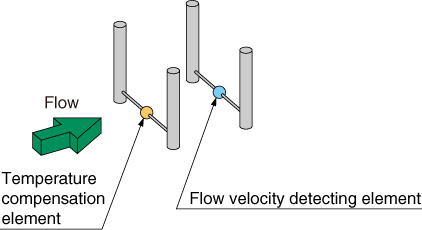

●Thermal type (Thermistor)

A heated thermistor is installed in the passage, and fluid absorbs heat from the thermistor as it is introduced to the passage. The thermistor's resistance value increases as it loses heat. Since the resistance value increase ratio has a uniform relationship to the flow velocity, the flow velocity can be detected by measuring the resistance value. To further compensate the fluid and ambient temperature, the temperature sensor is also built into the switch to allow stable measurement within the operating temperature range.

This flow switch uses L/min as the flow rate indicator unit. The mass flow is converted and displayed under the conditions of 0°C and 101.3 kPa and 20°C and 101.3 kPa.