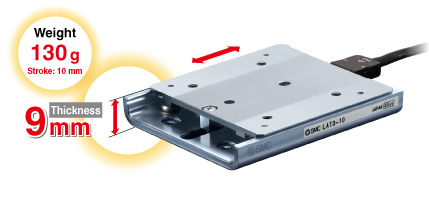

・The transportation, pushing and length measurement systems have been miniaturized through the use of a linear motor.

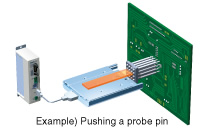

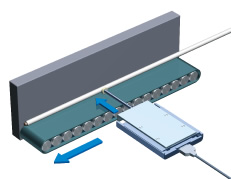

・Maximum pushing

force: 6N

Pushing a miniature load

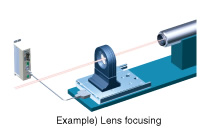

・Positioning repeatability:

± 5 μm

Positioning a workpiece

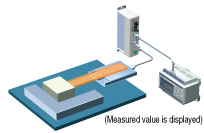

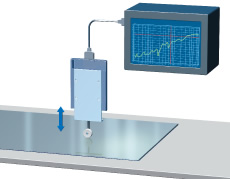

・Pushing measurement

accuracy: ± 10 μm

Parts measurement

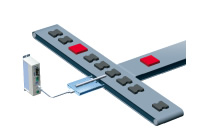

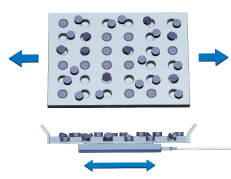

・Maximum operating

frequency: 500 cpm

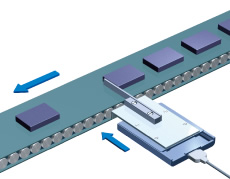

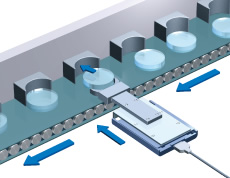

Rejection of non-conforming products, etc.

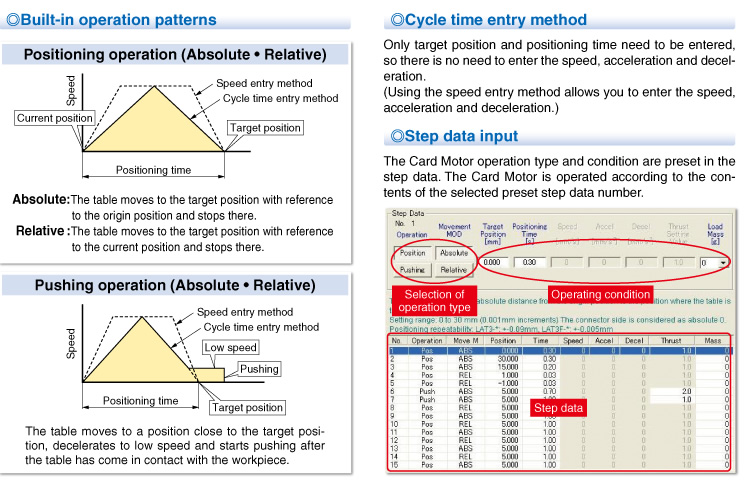

・0.5 kg → 1 kg

Just input 3 parameters:

Positioning time, Target

position, Load mass.

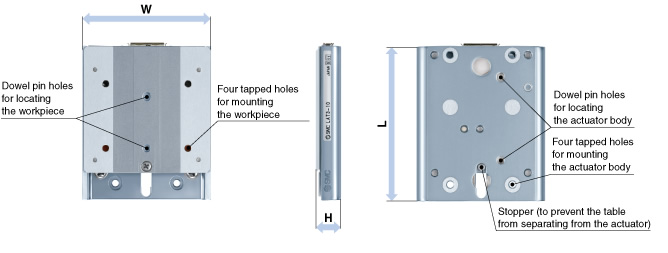

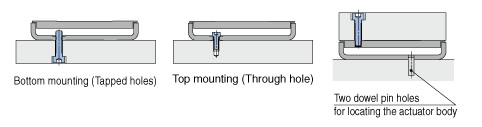

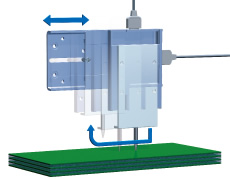

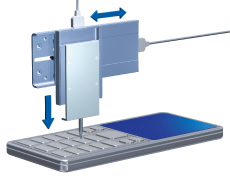

|How to Mount

Body Mounting

2 body mounting options

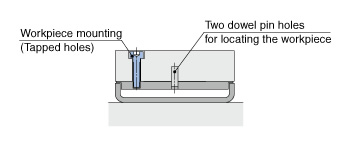

Workpiece Mounting

The table is provided with dowel pin holes for locating the workpiece as standard equipment.

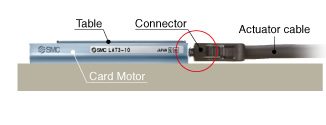

Cable Mounting

The cable connector does not protrude above the actuator.

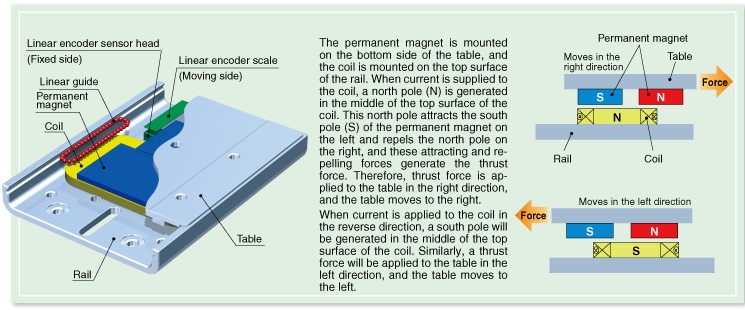

|Structure and Working Principle

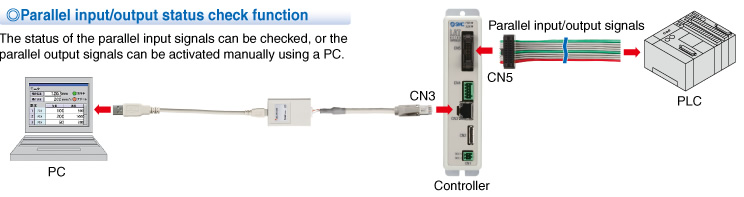

|Start-up time is reduced greatly with a system that is ready-to-use and easy to set up.

The functions described below makes the start-up quick and easy.

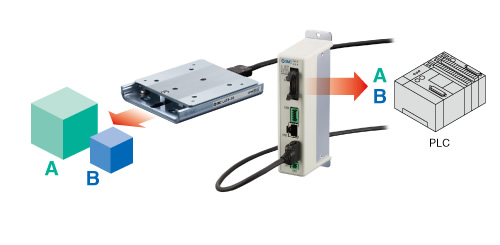

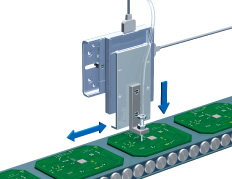

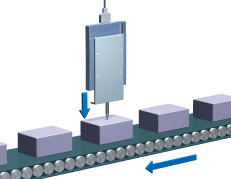

Function for measuring and differentiation of workpieces

The size of the workpiece can be measured based

on the table stopping position by driving the table

until it comes into contact with the workpiece.

The workpieces can be differentiated

or checked for quality using parallel

output signals that correspond to

preset table position ranges.

Furthermore, using the multi-counter

makes it possible to display the table

position and output up to 31 preset

points.

The size of the workpiece can be measured based

on the table stopping position by driving the table

until it comes into contact with the workpiece.

The workpieces can be differentiated

or checked for quality using parallel

output signals that correspond to

preset table position ranges.

Furthermore, using the multi-counter

makes it possible to display the table

position and output up to 31 preset

points.

|Application Examples

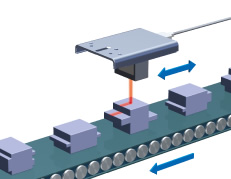

Examples of positioning applications

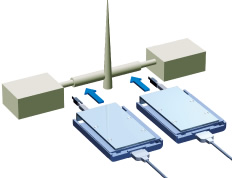

Sensor head movement and positioning

Component movement and positioning

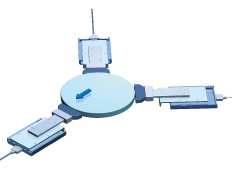

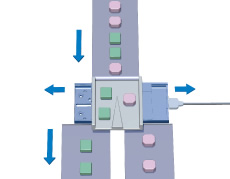

Electronic component pick and place

Component supply to tape

Component separation (escapement)

Workpiece alignment

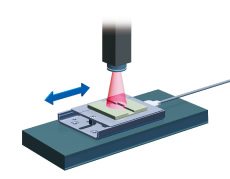

Examples of measurement applications

Measurement of workpiece height

Measurement of glass substrate thickness (multiple points)

Measurement of cable outside diameter

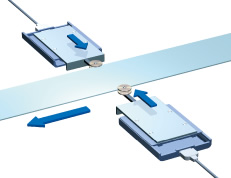

Measurement of tape thickness

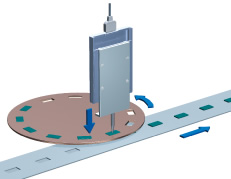

Examples of high frequency actuation

Alignment of components on pallet by vibration

Distribution of workpieces

Examples of pushing applications

Pushing of workpieces (soft touch)

Positioning of workpieces

Cutting of resin mold component runners

Tape alignment

Switch inspection

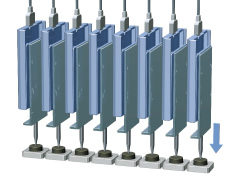

High-density layout