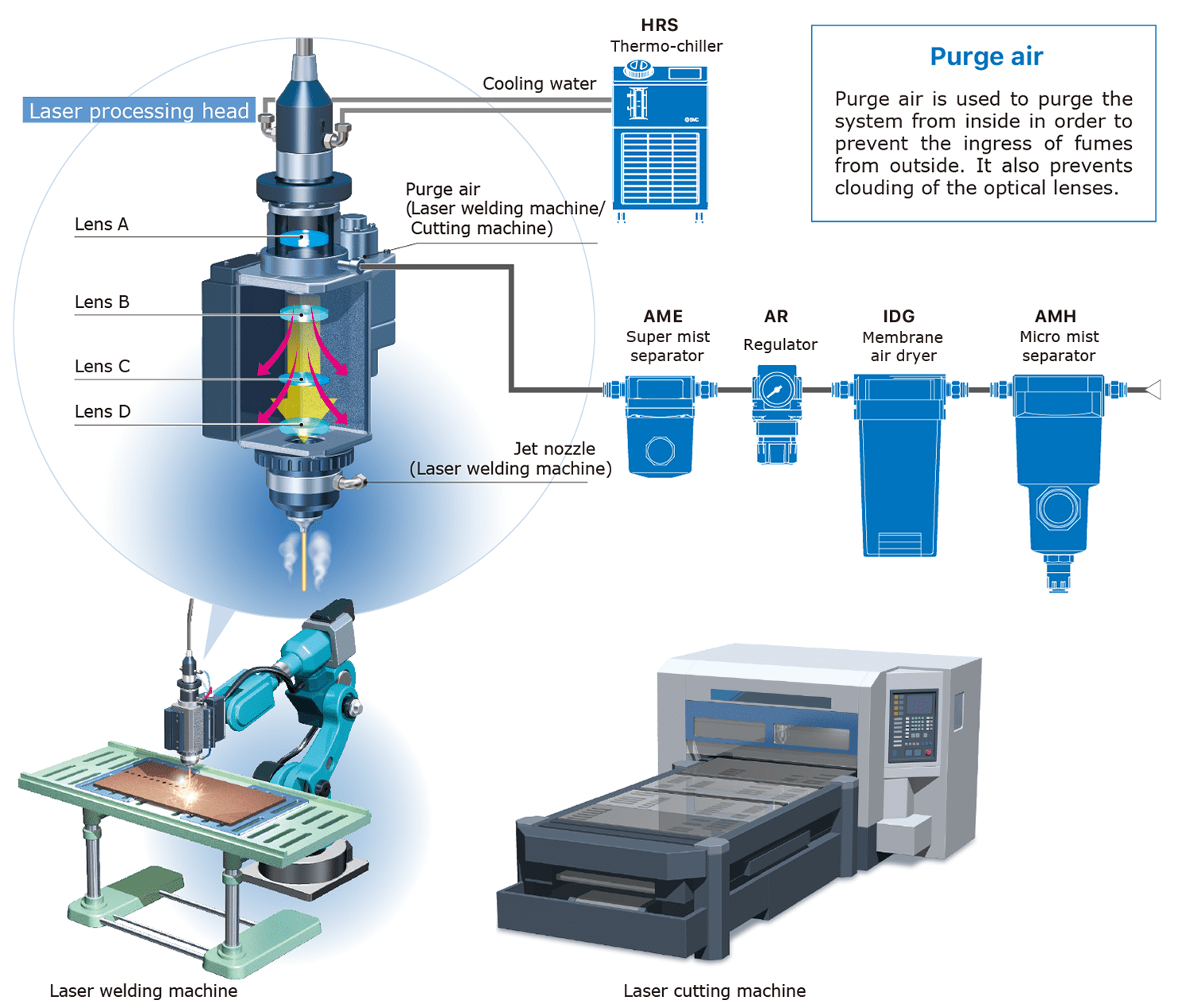

For Laser Processing

Heads

(Laser welding machines/Laser cutting machines)

Proposal for Air Preparation Systems

Prevents clouding of the optical lenses

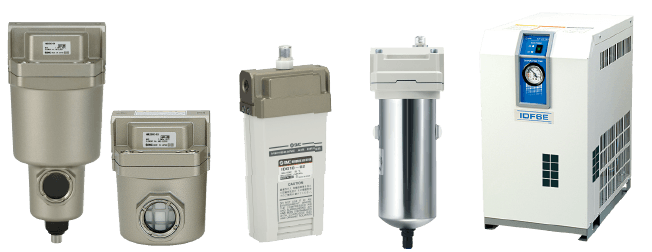

Proposal for Air Preparation System

System 1

- Compressed Air

Quality Grade

ISO8573-1:2010 - 1 : 4 : 1 *2

Example: 100 L/min (Inlet pressure dew point: 10°C) 0.1 MPa (Air blow set pressure)

-

-

Dust filtration,

Oil mist separationMicro mist separator with prefilter

AMH250C-02

-

Dehumidification

Membrane air dryer

IDG20-02

-

Pressure control

Regulator

AR20-02

-

Dust filtration,

Oil mist adsorptionSuper mist separator

AME250C-02

System 2

- Compressed Air

Quality Grade

ISO8573-1:2010 - 1 : 4 : 2 *2

Example: 300 L/min (Inlet pressure dew point: 10°C) 0.7 MPa (Inlet pressure)

-

-

Dust filtration,

Oil mist separationMicro mist separator with prefilter

AMH250C-02

-

Dehumidification

Membrane air dryer

IDG20-02

-

Pressure control

Regulator

AR20-02

Laser cutting machine

Laser welding machine

※1 Most manufacturers of laser processing machines/welding machines agree that the actuator air source should be separate from the purge air source that feeds the optical instrument. It is recommended that air from an oil-free compressor be used as the purge air source for the optical instrument.

※2 Select according to the air quality and other requirements of the laser head manufacturer.

Made to Order

-

With differential pressure gauge

For details

IDG□-X032

Can control the differential pressure

of the element -

Related Products

■Pamphlet